Polybenzimidazole (PBI)

Properties

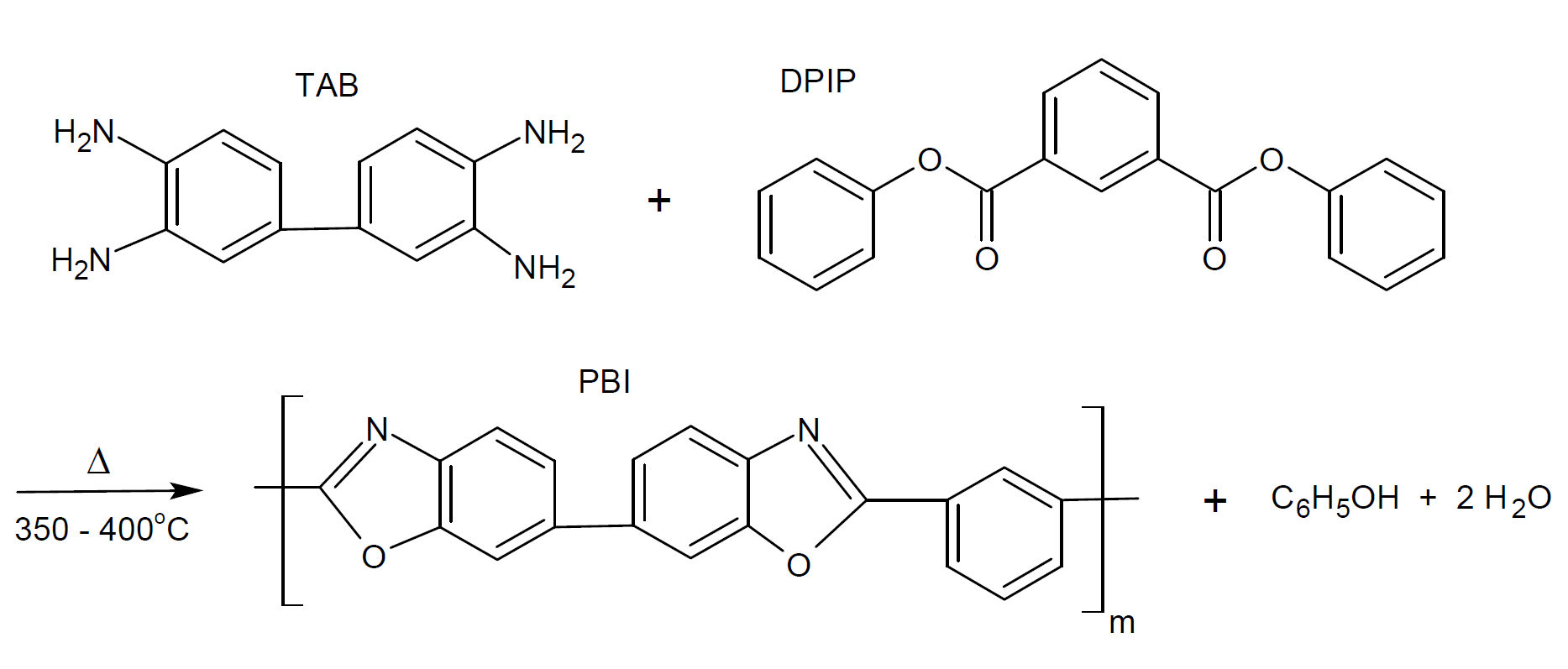

Polybenzimidazoles are a class of extremely heat-resistant heterocyclic thermoplastics. They are prepared from an aromatic tetraamine and an aromatic dicarboxylic acid or a derivative of it. A prominent example is the condensation reaction of diphenyl isophthalate and 3,3’,4,4’-tetraaminobiphenyl at 270° C with subsequent cyclization at temperatures between 350 and 400° C in an inert atmosphere.1

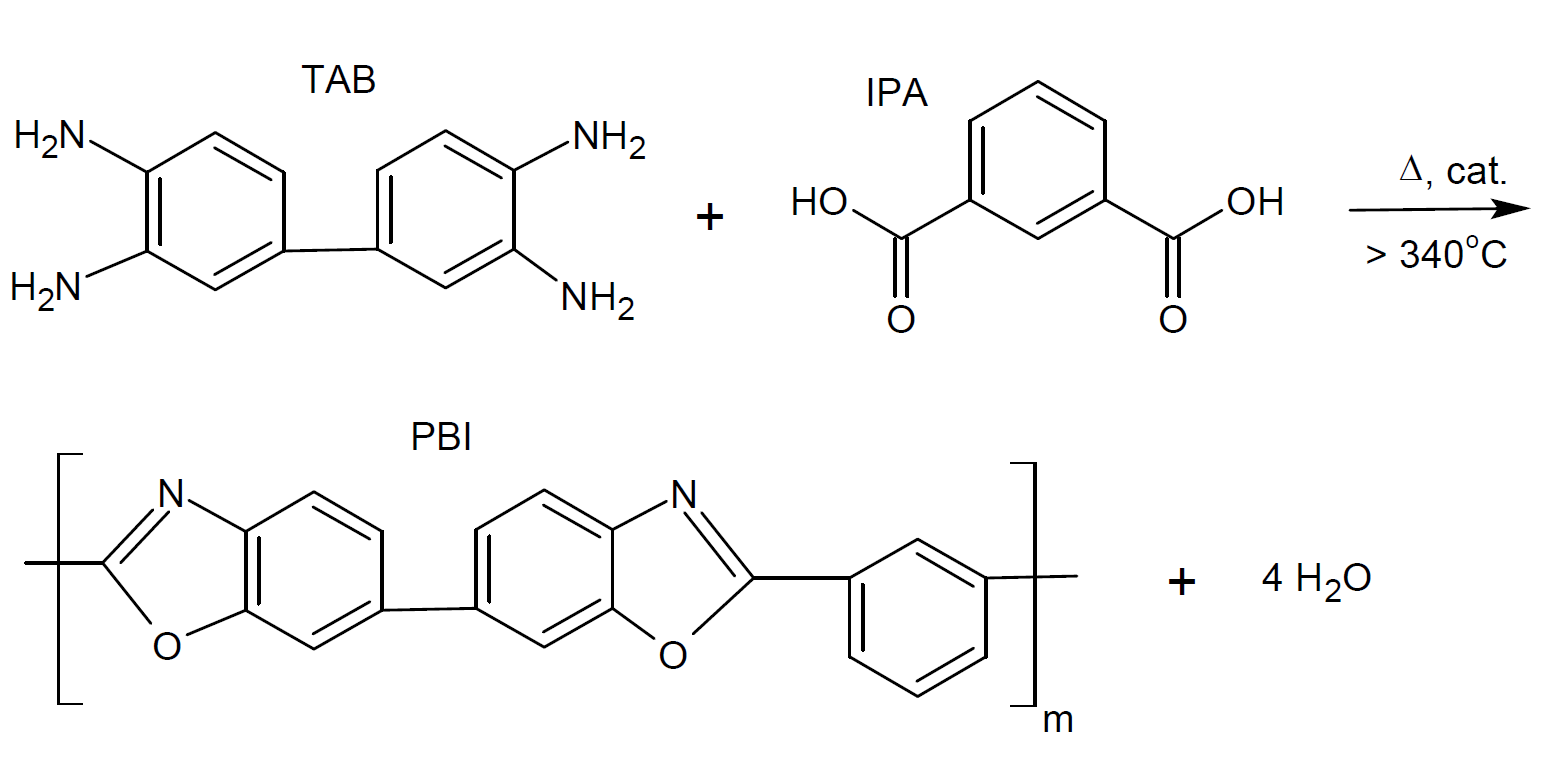

PBI can also be produced in a single stage process; in this case, isophthalic acid is reacted with 3,3’,4,4’-tetraaminobiphenyl at temperatures > 340° C and in the presence of a suitable catalyst:1

Polybenzimidazoles and their derivatives are very expensive and difficult to manufacture but have outstanding properties. In fact, the PBI shown above is one of the highest performing engineering plastics on the market and offers one of the highest heat resistance and service temperature of any unfilled thermoplastic. It has a very high glass transition temperature of about 425°C (800°F) and no melting point and its heat deflection temperature at 264 psi (1.8 MPa) is about 815°F (435°C). It also possesses outstanding heat stability and chemical resistance, including alcohols, hydrocarbons, chlorinated solvents, hydrogen sulfide, weak acids and bases, and many other chemicals. Its decomposition temperature is more than 1300°F (> 500°C).

Polybenzimidazoles have a very low level of ionic impurities and do not outgas (except water). These characteristics make them ideally suited to semiconductor applications (vacuum chamber applications). PBIs are also excellent thermal insulators and have outstanding wear resistance. Their extreme hardness make them difficult to machine. In most cases, diamond tools are recommended or required.

A major drawback of PBIs is their notch sensitivity. For this reason, sharp edges and corners should be avoided and all surfaces should be smooth.

COMMERCIAL Polybenzimidazoles

Polybenzimidazoles products (PBIs) are manufactured by PBI Performance Products2 under the trade name CELAZOLE®. Standard shapes and forms include fibers, sheets, rods and tubes.

Applications

Polybenzimidazoles are known for their high-strength and high-temperature performance. They find applications in many industrial fields including semiconductor, petrochemcial and aerospace industries. Major applications include heat resistant apparels, contact seals, wafer carriers, membranes for various separation processes, insulator bushings, and thermal isolators.

1E. W. Choe, J. Appl. Polym. Sci., Vol. 53, pp. 497 (1994)

2The InterTech Group purchased the PBI business from Celanese in 2005.